Sheet Metal Molding

Sheet Metal Forming Wide Application Area

Sheet metal forming is a production method used to give specific shape or form to metal sheets. As MARM Engineering, we offer metal processing services for a wide range of applications in various industries with our expertise in sheet metal forming and advanced equipment.

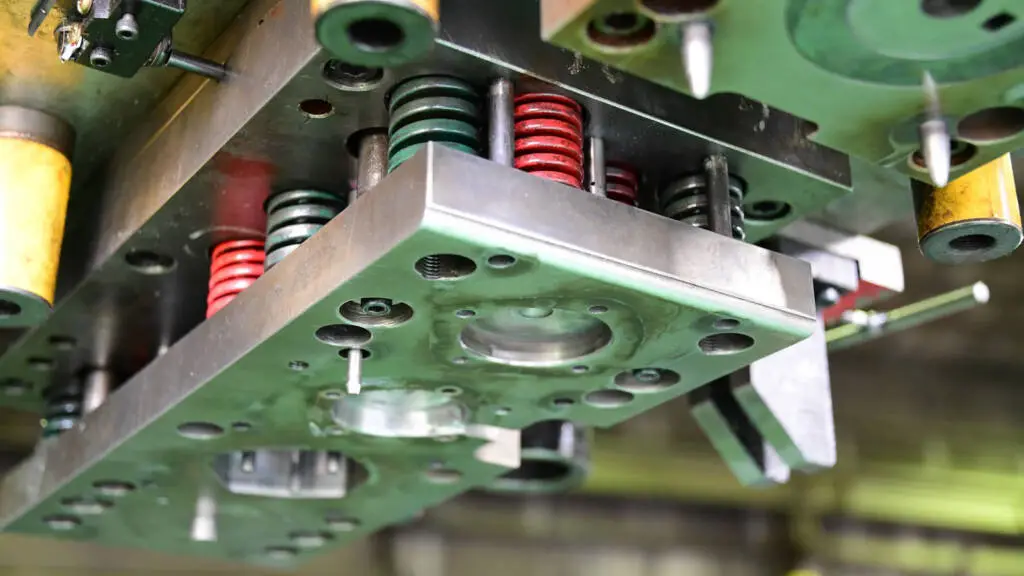

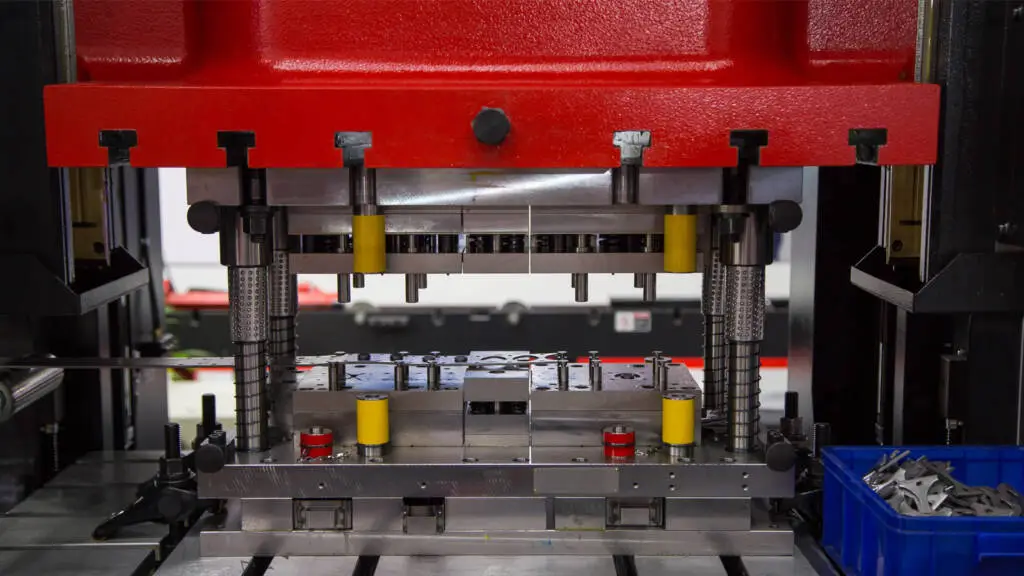

Design and Production Process

First, the desired part is designed in 3D in a computer environment, and after the design approval, the prototype is produced with 3D printing machines for necessary revisions and tests. Once the design and prototype are finalized, the mold design phase begins. The designed mold is manufactured on required machines and connected to a press with the necessary tonnage. The mold is used to obtain a print from the preferred material, resulting in the final product. This process enables the production of sheet metal parts with complex geometries and details. The result is durable and functional metal parts.