SLA Technology

Precision Detailed Production

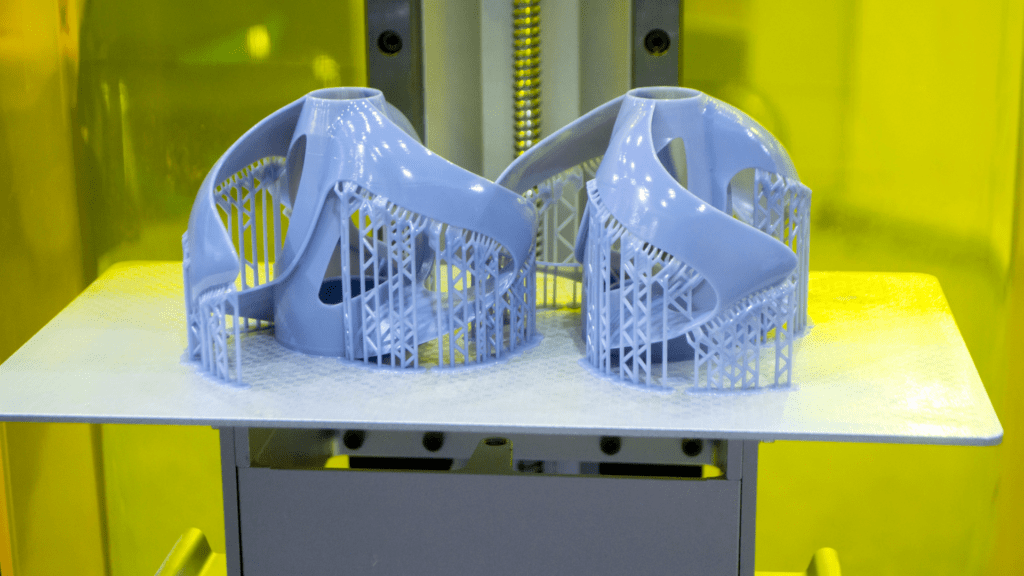

SLA (Stereolithography) is one of the leading 3D printing technologies, ideal for many applications requiring high precision and detailed production. At MARM Engineering, we harness the power and potential of SLA technology for you.

What is SLA Technology?

SLA works by adding resin in layers to the surface of a resin pool focused by a laser. As the laser solidifies the resin, each layer is merged with the previous one, ultimately creating the desired 3D print. This technology is ideal for the production of highly complex and precise parts.

Advantages of SLA Technology

Precision

Various Materials

Rapid Prototyping

SLA Material List

A high-resolution resin used for prototyping in parts that do not require strength.

It has high hardness and toughness, as well as tensile and bending strength.

Extremely strong, with high impact resistance and resistance to cracks and fractures during bending.

A transparent resin with similar properties to Basic resin.

It has high hardness and high temperature resistance.

It has high resolution and low elongation.

High temperature and chemical resistance, low water absorption.

It has high strength, toughness, and impact resistance.

A well-balanced multipurpose material. It is the most cost-effective among engineering resins.

It has very low hardness (Shore 40A), a soft-textured flexible resin.

It has low hardness (Shore 60A).

It has high hardness (Shore 90A). It has superior strength, resilience, and tear resistance.