Plastic Injection Molding

Precision and Efficient Production with Plastic Injection

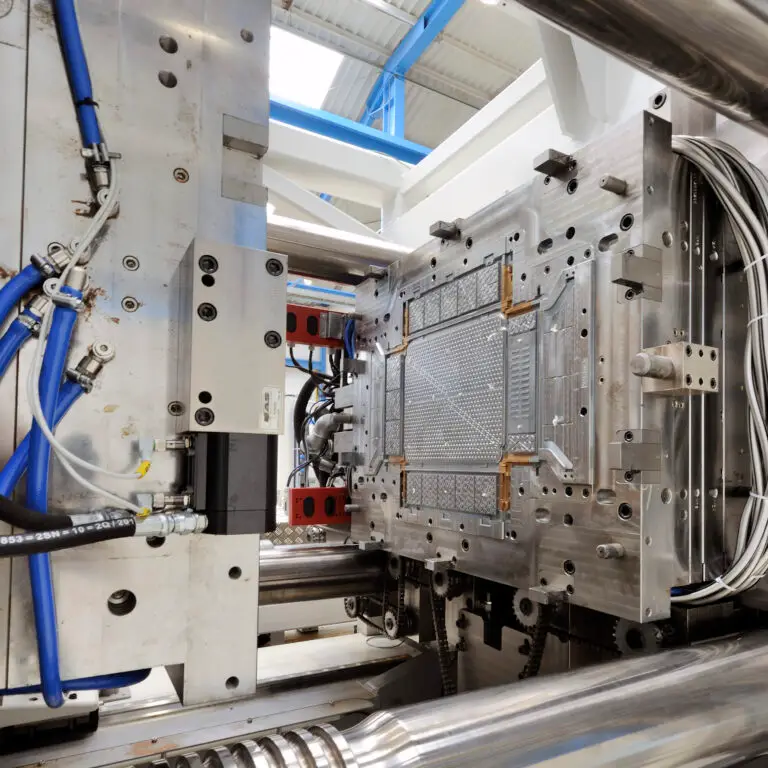

Plastic injection molding is an essential mass production method for the serial production of plastic parts. It is preferred in many industries such as automotive, white goods, furniture, machinery manufacturing, and medical. At MARM Engineering, we ensure the production of high-precision and high-quality plastic parts by utilizing our expertise in plastic injection molding and advanced equipment.

Design and Production Process

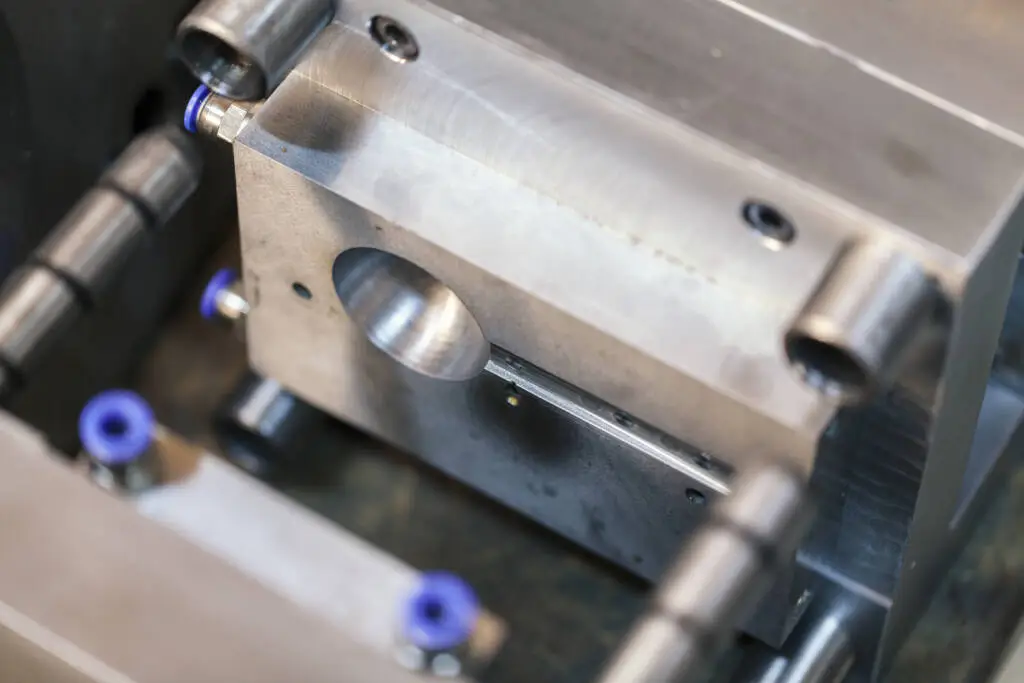

First, the desired part is designed in a 3D computer environment, and after design approval, a prototype is produced using 3D printing machines for necessary revisions and testing of the part. Once the design and prototype reach their final form, the mold design phase begins. The designed mold is produced in necessary machines and connected to the injection machine. The preferred liquid plastic material is injected into the mold to obtain the final product. This process enables the production of plastic parts with complex geometries and details. The result is durable, precise, and repeatable plastic parts.