MJF Technology

What is MJF Technology?

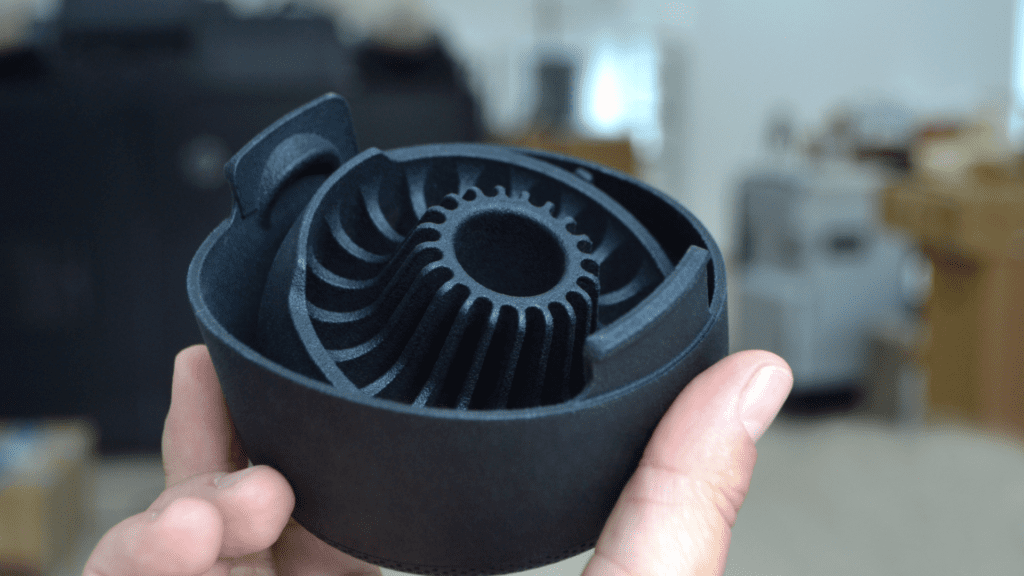

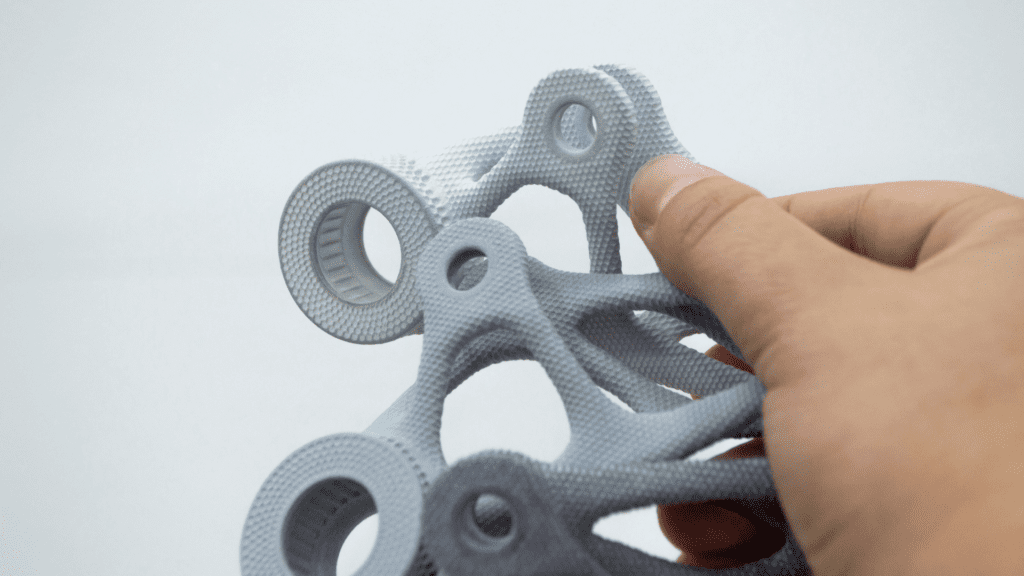

Multi Jet Fusion (MJF) is a 3D printing technology that combines thermal inkjet printing and powder bed fusion 3D printing methods. MJF enables the rapid and precise production of complex-geometry and high-quality plastic parts. MJF technology provides advantages such as high resolution, fast production, and the production of durable parts. This technology can be used in various applications, from prototypes to final products, and is particularly preferred in industrial production.

Stages of MJF Technology

Powder Preparation

The MJF printing process involves the use of polymer materials in powder form. Prior to printing, an appropriate powder material is prepared.

Creating the Printing Bed

A printing bed is created and the material layer is spread on top. Thermal Inkjet Printing: The thermal inkjet printing head applies ink layer by layer. The ink melts the material in specific areas of the printing bed and ensures the adhesion of the next layer.

Light Windows and Heated Rollers

There are light windows and heated rollers under the printing bed. The light windows control the temperature in specific areas of the material, while the heated rollers maintain the printing surface at the desired temperature.

Layer Fusion

After the thermal inkjet printing process is completed, the next layer of powder is applied, and the process is repeated to create the part layer by layer.

Cooling and Cleaning

After the printing process is completed, the part is cooled and removed from the printing bed. If necessary, excess dust particles are cleaned and the part is prepared for the final process.